In order to close the gap from simulation and reality, the control methods are also assessed with sensor noise and various controller frequencies. The controllers are evaluated for generalization by altering the kinematic model trailer wheelbase, hitch length, and velocity from the nominal case. This investigation quantifies the capabilities and limitations of both controllers in simulation using a kinematic model. The Linear Quadratic Regulator and the Deep Deterministic Policy Gradient (DDPG) are compared for robust control when the trailer is changed. Reinforcement learning, with neural networks as their function approximators, can allow for generalized control from its learned experience that is characterized by a scalar reward value. Finding alternative robust controllers when the trailer model is changed was the motivation of this research. However, real-world applications cannot expect to have an updated model for each new trailer. The closed form calculation of the gains for the Linear Quadratic Regulator (LQR) rely heavily on having an accurate model of the plant. The combination vehicles can be varied in wheelbase, hitch length, weight distributions, and tire cornering stiffness. Starting from random locations and orientations, paths are generated to loading docks with arbitrary pose using Dubins Curves. Two controller performances are assessed for generalization in the path following task of autonomously backing up a tractor-trailer. Basic economic calculations estimated the cost to operate the Flex-Ro machine for field phenotyping use at approximately $5.50/ha. The late season phenotyping data showed statistical differences between the fully irrigated versus deficit plots. The Flex-Ro was able to statistically distinguish between soybean variety emergence and maturity differences.

Positive correlations between the Spidercam and Flex-Ro phenotyping data were established. The system was verified in soybean research plots at the University of Nebraska-Lincoln (UNL) Spidercam phenotyping facility.

A suite of phenotyping sensors was installed onto the Flex-Ro to cover large field areas.

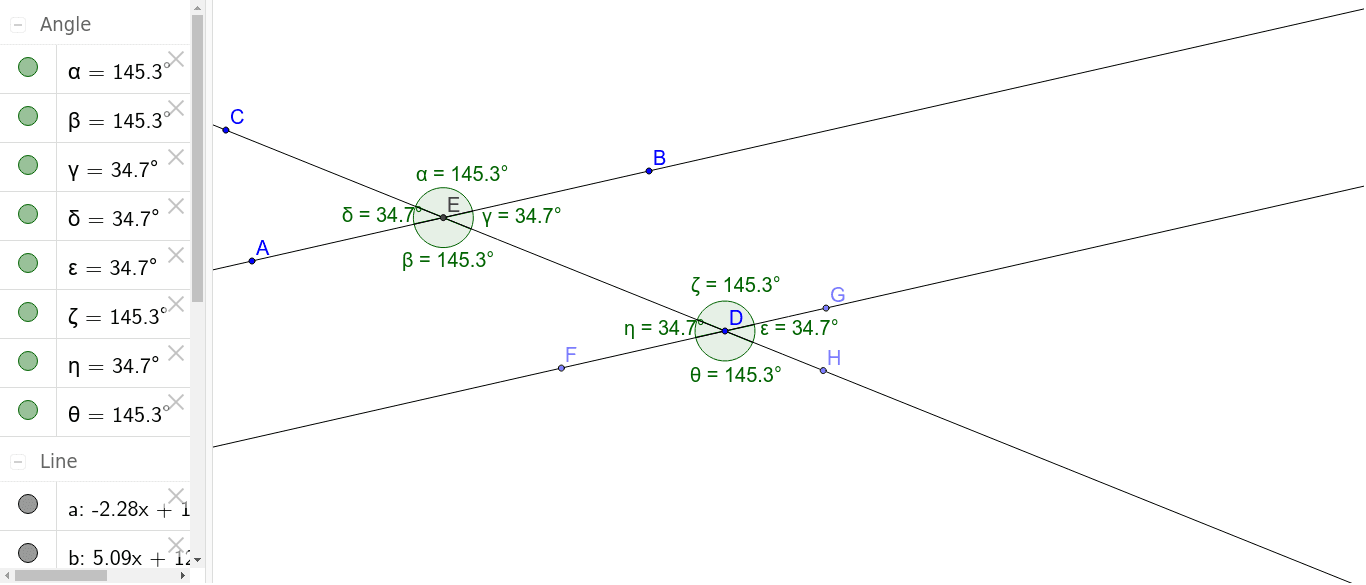

#Ackermann steering geometry calculator manual

The methods used to collect phenotyping data include drones, satellites, manual measurement, and ground rovers. High-throughput plant phenotyping is a continuously developing and evolving field of plant science. Waypoint guidance was implemented and demonstrated such that Flex-Ro could be programmed to follow complex paths and curves. The guidance system tracked within 4 cm of the guidance line 95% of the time at a travel speed of 4 kph. Autonomous field coverage was developed using global positioning system (GPS) guidance. Operators use the remote-control device to maneuver the machine in uncontrolled environments. The machine control architecture was developed for safe operation with redundant emergency stops and checks. This work presents the design and implementation of the control system for the Flex-Ro machine. The Flex-Ro (Flexible structured Robotic platform) was developed for use in large area fields as a multipurpose tool to perform monotonous agricultural tasks. However, the use of autonomous robots in commercial agricultural production is still limited. The use of robotics has been adopted in several industries to supplement labor, and accurately perform repetitious tasks. Optimization of crop production per unit of land requires scientists across disciplines to collaborate and investigate new areas of science and tools for data collection. The use of such geometry helps reduce tyre temperatures during high-speed cornering but compromises performance in low speed maneuvers.Research in agriculture is critical to developing techniques to meet the world’s demand for food, fuel, fiber, and feed. Some race cars use reverse Ackermann geometry to compensate for the large difference in slip angle between the inner and outer front tyres while cornering at high speed. Modern cars do not use pure Ackermann steering, partly because it ignores important dynamic and compliant effects, but the principle is sound for low speed manoeuvres.

#Ackermann steering geometry calculator full

Note that this may be difficult to arrange in practice with simple linkages, and designers are advised to draw or analyze their steering systems over the full range of steering angles. With perfect Ackermann, at any angle of steering, the centre point of all of the circles traced by all wheels will lie at a common point. The steering pivot points are joined by a rigid bar called the tie rod which can also be part of the steering mechanism, in the form of a rack and pinion for instance.

A simple approximation to perfect Ackermann steering geometry may be generated by moving the steering pivot points inward so as to lie on a line drawn between the steering kingpins and the centre of the rear axle.

0 kommentar(er)

0 kommentar(er)